- Home

- Products

- Beverage Industry

- Steinfurth

- Monitoring of Pasteurization

- Steinfurth Past Control System

Steinfurth Past Control System

Quick mobile torque measurement

Categories: Beverage Industry, Data Loggers, Monitoring of Pasteurization, Products, Steinfurth

- General Details

- Product Details

- Advantages

- Technical Data

- Documents

General Details

For producers of pasteurized beverages, pasteurization monitoring is essential. Insufficient pasteurization results in microbiologically objectable product charges; if pasteurization is carried too far, taste is affected. Therefore, an accurate measuring of pasteurizing units on a regular base can’t be neglected.

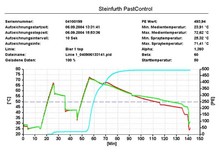

The Steinfurth Past Control system simplifies this task. The safe and simple operation requires only a short instruction to the operation personnel. The PU value can be read from the PU monitor’s display directly at the pasteurizer line.

The complete evaluation of the measured data is done at the PC. Clearly structured software offers graphical display as well as clearly arranged data storage. All measuring data files include a time stamp and a line ID code, so that all measurement data can be traced back. An unlimited number of loggers can be used.Functional overviewThe Steinfurth Past Control system for cans and bottles consists of a temperature logger, the PU monitor with interface (includes software for PC) and all necessary adapters. The logger is fitted to the original container and moved through the tunnel pasteurize. Meanwhile, the temperature at the selected (coldest) spot inside the container is measured and recorded. Optionally, the spray temperature is recorded, too (Dual channel version).

When the logger has left the tunnel pasteurizer, it is fitted to the PU monitor, and the number of pasteurizing units (PU) can be read from the PU monitor’s display. Afterwards, the logger can be started again and is ready for the next recording. The previous recordings remain in the logger’s memory and can be evaluated later.

The complete evaluation of the measured data is done at the PC. Clearly structured software offers graphical display as well as clearly arranged data storage. All measuring data files include a time stamp and a line ID code, so that all measurement data can be traced back. An unlimited number of loggers can be used.Functional overviewThe Steinfurth Past Control system for cans and bottles consists of a temperature logger, the PU monitor with interface (includes software for PC) and all necessary adapters. The logger is fitted to the original container and moved through the tunnel pasteurize. Meanwhile, the temperature at the selected (coldest) spot inside the container is measured and recorded. Optionally, the spray temperature is recorded, too (Dual channel version).

When the logger has left the tunnel pasteurizer, it is fitted to the PU monitor, and the number of pasteurizing units (PU) can be read from the PU monitor’s display. Afterwards, the logger can be started again and is ready for the next recording. The previous recordings remain in the logger’s memory and can be evaluated later.

Product Details

| Product Details | Specification |

| Industry | Beverages, Food Industry, Pharmacy |

| Employment | Measuring & Recording |

| Measurement Categories | Temperature |

| Objects | Beverages & Food |

| System | Yes |

| Automation Level | Fully Automatic Machine |

Advantages

- Single or dual channel temperature measuring

- Standard and special probe sizes available, can be fitted to various containers (bottle or can), using adapters

- Exact positioning of probe tip

- Simple operation and handling

- Small base space preserves thermal influence of surrounding containers

- Storage memory for up to 255 recordings (flexible partitioning, e.g. 250 recordings with 180 minutes each at 5 seconds interval)

- Programmable PU parameters

- Programmable measuring interval

- Programmable line ID

- Display of PU value and peak temperatures directly at the line

- Graphical evaluation and structurised data storage on the PC

- Password protected parameters

Technical Data

- Container type: Bottle or can

- Channels: 1 (Cold spot) or 2 (Cold spot and spray)

- Memory: 540672 measurings (1 channel) 2 x 270336 measurings (2 ch.)

- Interval: programmable (1 s … 24 h)

- Measuring range: -5°C … 80°C (32°F … 176°F) (-5°C…105°C / 23°F…221°F opt.)

- Accuracy: +/- 0.1 °C (+/- 0.18°F)

Documents