- Home

- Products

- Beverage Industry

- Steinfurth

- Carbon Dioxide Dosing

- LCS710P Laboratory Carbonation System

LCS710P Laboratory Carbonation System

Precise CO2 carbonation

- General Details

- Product Details

- Advantages

- Technical Data

- Documents

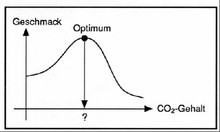

The quality enhancing properties of carbon dioxide are widely known within the beverage industry. Each beverage has its own specific content of carbon dioxide, particularly taste and flavor which are optimally developed. Until now it has been complicated, requiring a lot of time & money to produce beverage samples with individual CO2 content.

The LCS 710 P carbonates individual beverage samples with exactly predefined CO2 content. This unit makes it possible to reproduce, easily & quickly samples for analysis. The versatility of different carbonation settings helps us develop beverage samples for “sensoric” testing.

OPERATION:

– An injection probe is pushed into the test bottle. To start, a pressure of approximately 6 bars is generated within the bottle.

– Two defined shift phases are used to remove the air (or other gases) from the package headspace.

– Through a dosing piston an exact predefined quantity of CO2 will be added to the liquid. Un-dissolved CO2 will be “re-dosed” until it is absorbed completely by the liquid.

| Product Details | Specification |

| Industry | Beverages, Packaging Industry |

| Employment | Carbonation |

| Measurement Categories | CO2 |

| Objects | Beverages |

| Specifics | Regulated |

| System | Yes |

| Automation Level | Fully Automatic Machine |

- Cost savings during beverage development

- Simple adjustment for different bottle sizes

- Fully automatic function / Menu-driven input of bottle size and CO2 value

- Automatically secured safety cage

- Very good repeatability of results

- Double dosing speed selectable

- High accuracy also with PET bottles and cans regardless of the temperature

- Automatic head space purging with CO2 gas

- Reduced foaming of the beverage samples

- Optimized automatic cleaning program

- Low maintenance effort by of automatic lubrication

- Bottle size (other on request):

Glass: Standard up to 360mm height / 100mm diameter

PET: Standard up to 330mm height / 90mm diameter - Dosing capacity: 0 to 10 g/l (depending on the temperature and solubility)

- Accuracy: 0.1 g/l

- Max. bottle-pressure: 7 bar

- Electric: 230V / 50 Hz (115V / 60 Hz)

- Dimensions: 560 x 610 x 280mm (W x H X D)

- Weight: 33 kg