- Home

- Products

- Beverage Industry

- Steinfurth

- Carbon Dioxide Dosing

- CARBOFRESH®

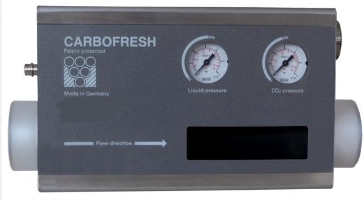

CARBOFRESH®

New generation of inline carbonation for wine refreshing

- General Details

- Product Details

- Advantages

- Technical Data

- Documents

Carbon dioxide is known as one of the major refreshing and taste impacting ingredients of wine (beer or soft drinks).

Effective adjustment of the carbonation level (carbonation for white and rose wines, or CO2 reduction for red wines) is an important process step in adjustment & production of the optimal wine quality.

Quality improvement in white and rosé wines

The unique incorporation of fine carbon dioxide bubbles lends freshness and lightness to the flavour and body of wines.

Even with dense and voluminous wines, it imparts aromas. The subtle carbon dioxide bubbles make white and rosé wines fresher, livelier and aromatic.

De-carbonation and CO2 adjustment in red wines

Excess and disturbing carbon dioxide can be removed from red wines. Instead of charging with carbon dioxide, plain nitrogen is used. The Carbo-fresh® processor makes it easy to adjust the optimal content of carbon dioxide in wines. The wine is simply passed through the system and transferred unpressurized into the tank.

The device works purely pneumatically and doesn’t need any electric energy supply.

The desired carbon dioxide concentration is set directly at the device itself.

If product flow drops below a minimum flow rate, the device is automatically deactivated.

When the product flow increases, carbonation is activated again.

OPERATION:

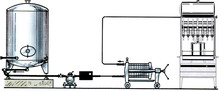

A feed pump (not included) presses the beverage through a built-in venturi injector, where the desired amount of CO2 is added. The CO2 bubbles dissolve in the downstream mixing stage.

| Product Details | Specification |

| Industry | Beverages |

| Employment | Measuring |

| Measurement Categories | CO2 |

- Quick return of investment

- Low maintenance requirements

- Accuracy and consistency of product quality

- Easy installation and operation

- No electrical connections or control modules

- High efficiency

- Automatic activation / deactivation

- Flow rate: 1.000 – 30.000 l/h (265 – 7833 gal/h)

(depending on injector size) - CO2 concentration: 0-1.8 g/l / 0-0.8 vol (continuously variable, temperature-dependent)

- Required feed pump pressure: 6 bar / 87 PSI

- Maximum operating pressure: 7 bar / 102 PSI

- CO2 supply pressure: 7 bar / 102 PSI

- Dimensions (LxHxD) in mm: 300 x 160 x 100

inch: 11.8 x 6.3 x 3.9 - Pressure loss: approx. 0.7 – 2.0 bar (10 – 29 psi)