- Home

- Products

- Sample Handling Components

- Perma Pure

- Gas Sample Dryers

- MD-R Series Gas Sample / Membrane Air Dryers

MD-R Series Gas Sample / Membrane Air Dryers

- General Details

- Features

- Principle of Operation

- Performance

- Video Presentations

- Documents

Perma Pure MD-R™-Series Membrane Air Dryers use exclusive Nafion® selectively permeable membrane tubing to continuously dry gas streams removing only water vapor. These Air Dryers operate over a wide range of temperatures, pressures and flow rates, and dry to dew points as low as -60°C.

- Flow rates up to 4 l/m

- Operating temperatures to max. 120° C

- Operating pressures to 100 psi (absolute)

- Straight or coiled configuration

- Corrosion resistant

- Standard dew points to – 25° C, with – 60° C possible in special cases (contact factory)

- No loss of analytes

- No moving parts

The MD-R Series Membrane Air Dryers transfer moisture from one gas stream to a counter-flowing purge gas stream, much like a shell-and-tube heat exchanger transfers heat. Water molecules permeate through the Nafion® tube wall, evaporating into the purge gas stream. The water concentration differential between the two gas streams drives the reaction, quickly drying the air or gas. Purge gas should be dry (-40°C dew point) air or other gas. If no dry gas is available, a portion of the gas dried by the MD-Series dryer can act as the purge gas in a split-stream or reflux method. Visit the Purge Gas Configurations page to learn more about the purge methods Perma Pure customers deploy in their equipment.

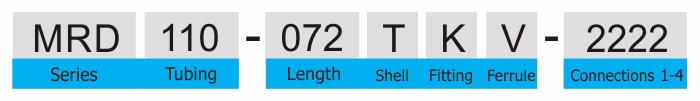

Intelligent Product Numbering System

Perma Pure offers the MD-R Series Membrane Air Dryer with two sizes of Nafion® tubing and in a variety of lengths and connection types. Choose the size based on your flow rate and dryness requirement and build your MD dryer according to the selection guide and the part number table below:

|

|

Recommended Sample Gas Flow Rates:

0.1-2 lpm: MDR-070 Series

1-4 lpm: MDR-110 Series

Selection Guide Notes – 2MDR-070 and MDR-110 offer approximately the same drying performance. Specify MD-110 when pressure drop is a concern, MD-070 to minimize dead volume. For higher flow rates, please see our PD-Series dryers.

MD Dryer Series Performance Curves

NOTE: The pressure drop is per inch of dryer. For example, the pressure drop of 100 ml/min through an MD-050-24 is equal to 2.4 inches of water. These performance curves are based upon an inlet sample dew point of 20°C, a purge gas with a dew point of -40°C, and a purge flow rate which is 2-3 times the sample flow rate. For conditions higher than ambient temperature, it is assumed that the first half of the dryer will be used to bring the dew point down to ambient. For this reason, read the value of the next shorter dryer. For example, a stream with an initial dew point of 50°C, flowing at 2 slpm; an MD-070-48 should yield an outlet dew point of 6°C, the performance of the 24″ unit.

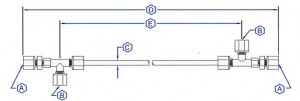

Dimensions

| Model Number | A | B | C | D | E | A | D | E | ||

| Single Tube of 0.050″ O.D. Nafion |

Fluorocarbon or Polypropylene |

Stainless Steel |

||||||||

| For Engineering drawings, click part number: | MD-050-F or P | MD-050-S | ||||||||

| MD-050-12 | 1/8″ | 1/8″ | 1/8″ | 14″ | 10-5/8″ | 1/8″ or 1/16″ | 14″ | 11-1/2″ | ||

| MD-050-24 | 1/8″ | 1/8″ | 1/8″ | 26″ | 22-5/8″ | 1/8″ or 1/16″ | 26″ | 23-1/2″ | ||

| MD-050-48 | 1/8″ | 1/8″ | 1/8″ | 50″ | 46-5/8″ | 1/8″ or 1/16″ | 50″ | 47-1/2″ | ||

| MD-050-72 | 1/8″ | 1/8″ | 1/8″ | 74″ | 70-5/8″ | 1/8″ or 1/16″ | 74″ | 71-1/2″ | ||

| Single Tube of 0.070″ O.D. Nafion | Fluorocarbon or Polypropylene | Stainless Steel | ||||||||

| For Engineering drawings, click part number: | MD-070/110-F or P | MD-070/110-S | ||||||||

| MD-(070 or 110)-12 | 1/4″ or 1/8″ | 1/4″ | 1/4″ | 14-1/4″ | 10″ | 1/4″ or 1/8″ | 13-3/4″ | 10-3/4″ | ||

| MD-(070 or 110)-24 | 1/4″ or 1/8″ | 1/4″ | 1/4″ | 26-1/4″ | 22″ | 1/4″ or 1/8″ | 25-3/4″ | 22-3/4″ | ||

| MD-(070 or 110)-48 | 1/4″ or 1/8″ | 1/4″ | 1/4″ | 50-1/4″ | 46″ | 1/4″ or 1/8″ | 49-3/4″ | 46-3/4″ | ||

| MD-(070 or 110)-72 | 1/4″ or 1/8″ | 1/4″ | 1/4″ | 74-1/4″ | 70″ | 1/4″ or 1/8″ | 73-3/4″ | 70-3/4″ | ||

| MD-(070 or 110)-96 | 1/4″ or 1/8″ | 1/4″ | 1/4″ | 98-1/4″ | 94″ | 1/4″ or 1/8″ | 97-3/4″ | 94-3/4″ | ||

| MD-(070 or 110)-144 | 1/4″ or 1/8″ | 1/4″ | 1/4″ | 146-1/4″ | 142″ | 1/4″ or 1/8″ | 145-3/4″ | 143-3/4″ | ||

Perma Pure has created a series of short video presentations to describe the basic functionality of some of our products. The videos are posted below.

Nafion Tubing Basic Functionality

[youtube id=”-arILnvePC4″ align=”left” mode=”normal” autoplay=”no” aspect_ratio=”16:9″ maxwidth=”400″ parameters=”https://www.youtube.com/watch?v=-arILnvePC4&feature=youtu.be” grow=”yes”]