- Home

- Products

- Process Measurements

- Extrel

- Materials Research

Materials Research

- General Details

- Overview

Scientists involved in the study of Materials Research are analyzing the surfaces, structures and properties of various materials for many industries. This requires the use of a Mass Spectrometer with not only high sensitivity and resolution, but also precise ionization control and energy analysis capabilities.

Scientists rely on Extrel’s Systems and Components for surface analysis of various materials that are used every day in an array of industries including semiconductor, aerospace, biomedical, nuclear, ceramics, automotive and medical/surgical. Where high purity is critical, such as in the ceramics, automotive and medical/surgical materials markets, Extrel’s systems are ideal to perform the Outgassing Studies necessary.

Materials Research Applications

Catalysis

Researchers studying the use of Catalysts strive to better understand how they function and respond under different conditions. Tracking the inlet and outlet of the reactor helps the investigator develop an understanding of the catalytic reaction. The composition of the outlet stream provides information about the reaction, efficiency and selectivity of the catalyst. For that reason, scientists rely on Extrel products to provide the fast, accurate and flexible analysis needed to perform such laboratory experiments.

Laser Ablation

Outgassing Studies

Analysts use Outgassing Studies to determine the chemical and physical properties of materials that are under various temperature and pressure conditions. Outgassing research analyzes materials used in the production of Aerospace and Semiconductor devices. This application is also well-suited to analyze devices such as Medical/Surgical Equipment, Automotive Parts and High Precision Ceramics, where high quality results are critical for successful research studies.

Scattering

One technique used to characterize the physical and electronic properties of the surface of a material is HeliumScattering and mass spectrometry. A beam of atoms, usually Helium, is aimed at a surface, and atoms from the surface are ejected. Mass Filters are used to measure the atoms that are scattered, and to pinpoint the angle and time at which the scattering atoms are being released (time of flight analysis). Since the events of this non-destructive surface science method happen quickly, this application requires the use of mass filters that provide high stability and fast response times.

Secondary Ion Mass Spectrometry

Secondary Ion Mass Spectrometry (SIMS) is used to detect and characterize trace elements at or near the surface of a solid or thin film allowing researchers to understand the chemical composition of the surface. This surface science technique requires the use of systems with very high sensitivity and the ability to perform high resolution energy analysis. SIMS is useful for a wide variety of surface analysis. For example, SIMS can be used to detect and analyze contaminants on a surface, analyze materials and devices to ensure the quality of specific products, and study atomic scale defects that may occur in the manufacturing of semiconductor chips or other materials.

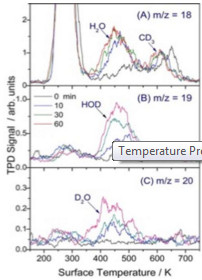

Temperature Programmed Desorption

Temperature Programmed Desorption (TPD) is one of the most widely used surface analysis techniques available for materials research scientists. To analyze material compositions, surface interactions and surface contaminates, scientists rely on Extrel’s Mass Spectrometry systems.

Thermogravimetric Analyzer/ Mass Spectrometer (TGA-MS) Materials Research

Thermogravimetric analysis (TGA) is a powerful approach to the study of the thermal behavior of solid and liquid samples. The interface of TGA with a quadrupole mass spectrometer allows the researcher to characterize and quantify the compounds in the off-gas in real-time along with each mass loss.

In the fermentation process, the growth of bacteria and production of drugs takes place under very tight conditions. The aeration rate, temperature and dosage of nutrients are regulated very closely during several stages of the process. The Quadrupole Mass Spectrometer is used to provide full, fast and precise analysis of the incoming air and the off-gas from the Fermentor. The results are used to calculate the Respiratory Quotient (RQ), a major parameter in controlling growth and health of the bacteria. In different stages of a batch fermentation process, the RQ value changes, thus allowing for optimum and efficient drug production. The additional analysis of minor concentrations of by-products allow for rapid process adjustment to avoid undesired reactions.