- Home

- Products

- Sample Handling Components

- Genie

- Membrane Probes

- Genie 745 Preconditioning Assembly

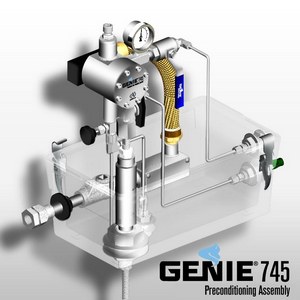

Genie 745 Preconditioning Assembly

- General Details

- Benefits

- Features

- Documents

The increased production of natural gas from unconventional sources (shale gas formations and deep-water offshore platforms) has created a need for more sampling points closer to the wellhead and gathering sites. Different types of contaminant analyses are being performed (H2S, CO2, O2, H2O) on these gas streams so processing plants can use the analysis data for optimal process control. Large quantities of free liquids are often continuously present at these sample points – hydrocarbons, water, corrosion inhibitors, methanol, and scavengers for example. This poses a challenge for traditional sampling equipment that was designed for transmission quality gas with a minimal amount of liquid entrained in the gas.

This Sampling System is intended for use when analysis for process control is being performed on a natural gas stream having large quantities of free liquids continuously present. The purpose of the 745 is to provide the analyzer with a liquid free, low pressure sample.

The 745 consists of a vertically mounted, non-membrane tip Direct-Drive™ probe for sample extraction, Genie® Membrane Separator™, Avenger™ Coalescing Filter for liquid removal, and Genie® Heated Regulator for pressure reduction without JT cooling effects. The membrane separator, coalescing filter and heated regulator have been designed into a compact single unit that mounts on top of the PGSS probe, inside of an insulated enclosure.

Although the gas exiting the 745 is liquid free and at low pressure, heat trace tubing may be required depending on the dew point temperature of the gas. It is also recommended that a Genie® Membrane Separator™ with Liquid Block™ be installed as close to the analyzer as possible in case of heat trace failure or major process upsets.

- Allows contaminant analyses to be performed on natural gas streams where traditional sampling equipment cannot be used

- Protects the analyzer from liquid contamination, minimizing analyzer down time and maintenance

- No need to depressurize line for PGSS probe insertion/retraction

- Prevents regulator freeze-ups

- No cutting, drilling or additional mounting hardware required

- Directly mounts on pipeline

- Fits between pipe taps with 7” center to center spacing that are commonly found on meter runs

- Patented Genie® Membrane Technology™

- Direct Drive™ style adjustable length insertion probe

- Heated pressure regulator

- Plug and Play compact design